Policy Update

Kumar Ankit

Background

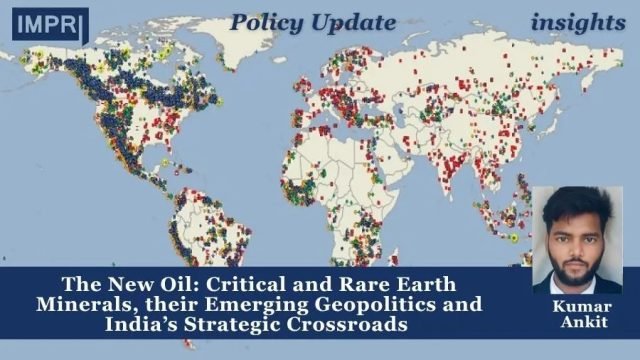

Critical minerals, from lithium and cobalt to rare earth elements, have become linchpins of the modern economy. They are the new oil of the twenty-first century for electric vehicles, semiconductors, solar panels, wind turbines, and advanced batteries and are critical for not only clean energy but also medical, defence, and aerospace. Critical minerals are also crucial for developing the digital and the green economy. But what are critical minerals exactly?

Critical minerals are those minerals that are vital for both economic and national security and are vulnerable to supply chain disruptions. Rare earth elements, or REEs, are a subsection in this list, and they come under critical minerals. Each country classifies its own critical minerals based on its needs and its availability. For example, India has a list of 30 critical minerals of strategic importance. The US has a list of 50 minerals that was updated in 2022, which even includes minerals like antimony, arsenic, and even zinc, which are not a part of India’s list.

China’s list, on the other hand, is similar to India’s, but there it’s known as their list of strategic minerals. Now these minerals are critical for two main reasons. One is their importance in the development of the economy, be it in use in electronics, technology, communications, or renewable energy. The other is their availability. They are unevenly distributed around the globe. For example, cobalt, which is essential for lithium-ion and other rechargeable batteries for electric vehicles, is largely found in the Congo, while lithium, another crucial mineral for batteries and solar panels, is found in Argentina, Bolivia, and Chile (Lithium Triangle). Nickel, on the other hand, is found in Indonesia.

At a similar breadth, rare earth elements are a group of 15 lanthanides plus scandium and yttrium, i.e., 17 metallic elements. They include elements like scandium, yttrium, neodymium, europium, and terbium. Despite their name, these elements are not especially rare. They are characterised by their high density, high melting point, and high conductivity and are used in alloys for substances like permanent magnets, semiconductors, radiation shielding, and other technologies.

In terms of availability, China is home to most of the rare earth minerals and is the largest producer of rare earth elements in the world. They’re also found in Vietnam and Australia. And while India does have upwards of 8 million tonnes of deposits, it takes a minimum of 10 years to get the mines up and running to actually produce these rare earth elements.

Global Landscape

Controlling these raw materials has become as much a matter of national security and diplomatic leverage as traditional minerals like oil or steel. Today, governments worldwide are scrambling to secure stable sources: they are boosting domestic exploration and recycling, striking bilateral mining deals, forging multilateral partnerships, and even stockpiling key minerals. The result is an increasingly fraught global contest, where alliances and trade conflicts now turn on who controls critical metals.

Through decades of strategic investment, China today dominates every stage of the critical-mineral value chain, from mining and refining to manufacturing. China acts as both a supplier and a choke point, and this monopoly gives it tremendous leverage. The 2010 temporary halt of China’s rare earth export to Japan, during a diplomatic spat, triggered global supply shocks. The spring 2025 export control on several REEs caught automakers and tech firms off guard. India’s response to this export control on strategic minerals has been twofold: shoring up friendly sources (e.g., strengthening ties with Australia’s Critical Minerals Facilitation Office and signing ministerial pacts) and hedging through alliances.

Predictably, other powers are reacting. The United States, the European Union, Japan, and others have launched various strategies to diversify supply away from China. For example, Washington’s approach includes incentives for domestic mining and recycling, trade deals with “trusted partners”, and new alliances such as the U.S.-led Minerals Security Partnership and the Indo-Pacific Economic Framework. The EU has its own toolkit, emphasising homegrown production and recycling and deeper ties to producing countries.

Public reports note that even China, which is the world’s largest importer and refiner of these minerals, faces “familiar challenges of dependency, supply disruption, and price fluctuation.” In practice, resource-rich nations are also flexing their muscles. Indonesia’s nickel export ban to stimulate domestic battery plants and Chile’s and Argentina’s new mineral-nationalist policies show that supply can be constrained at multiple ends. Such inward-looking moves, though understandable, risk further straining the chain.

Trade frictions have already surfaced. The US-China trade war of recent years is now spilling into mineral geopolitics. Both sides see critical minerals as strategic bargaining chips: China’s export controls in 2023–24 (e.g., on gallium, germanium, and REEs) were widely viewed as retaliation over tech tariffs, while U.S. policy has contemplated steep tariffs on Chinese EV batteries and electronics to nudge supply chains toward allies. Countries like Brazil have now decided to declare strategic minerals a matter of ‘national sovereignty’. Meanwhile, Japan, the EU, and the U.S. have pursued WTO cases or consultations in response to Chinese restrictions.

At the same time, new multilateral initiatives aim to “de-risk” from over-dependence on any single supplier. For instance, the Quadrilateral Security Dialogue (the “Quad” of the US, Japan, Australia, and India) announced in July 2025 a Critical Minerals Initiative spanning upstream exploration through downstream manufacturing. The Quad plan explicitly aims to diversify sourcing and “reduce China’s market leverage” by jointly financing mining projects, sharing geological data, and co-developing processing technologies. Likewise, the EU’s new “Global Gateway” investment package directs over €12 billion to alternative supply corridors (for example, into Central Asia). These efforts underscore that critical minerals are now a centrepiece of geopolitical strategy, not just economic policy.

India’s Position

A committee formed by the Indian Ministry of Mines in November 2022 identified 30 critical minerals, of which 24 minerals were also listed under Part D of Schedule I of the Mines and Minerals Development and Regulation Act, 1957 (MMDR Act, 1957). This inclusion of 24 minerals means that the central government has the sole authority to auction mining leases and composite licences for these specific minerals. India currently produces only 1 per cent of global output in critical rare earth minerals even though it has 6 per cent of the global reserves. India imports virtually all of its key battery and permanent-magnet minerals and is 100% import-dependent for lithium, cobalt, nickel, and germanium.

In 2024-25, India still imported roughly 53,748 tonnes of rare-earth magnets for industry (mostly from China). In short, India has been “underprepared” for the mineral crunch, with industry leaders cautioning that the country is still vulnerable to supply disruptions. In early 2025, the Indian cabinet approved a National Critical Minerals Mission (NCMM) with a large outlay (about ₹34,300 crore over seven years) to secure raw materials for the energy transition. The mission aims to boost domestic exploration (1,200 projects and 100 mining blocks to auction by 2031) and to facilitate overseas acquisitions and partnerships. In addition, production-linked incentive schemes have been extended to cover battery components and even recycling.

Recognising that domestic supply alone cannot be scaled up overnight, India has also embarked on aggressive mineral diplomacy. In 2019 the government created Khanij Bidesh India Ltd. (KABIL), a joint venture of three state miners (NALCO, HCL, and MECL), specifically to scout and acquire overseas critical mineral assets. KABIL’s early deals exemplify this strategy. In 2023 it signed a pact to develop Argentine lithium blocks, India’s first overseas lithium exploration agreement. Negotiations are underway for more Latin American projects: KABIL is reported to hold four mining concessions (including REEs) in Latin America in partnership with Coal India, and it is in talks with Argentina, Peru, and Bolivia for additional sites.

In Africa, India has quietly been in discussions with Zambia, Zimbabwe, and others: the finance secretary noted that KABIL and NMDC (another state miner) are “looking at partnerships in Africa” for cobalt, copper, and more. India has also signed MoUs on cooperation with Australia, Argentina, the Democratic Republic of Congo, and others to facilitate exploration and investment. India’s support for the G20 Minerals Security Dialogue for clean energy stimulates how India engages in the global platform. These moves span the mining value chain: agreements cover everything from junior exploration to joint refining projects (for example, IREL recently commissioned a rare-earth magnet plant in Visakhapatnam to cut dependence on imports).

Future Pathways

India now stands at a crossroads. On one hand, it faces a stark choice between technological growth and strategic vulnerability: without assured supplies of lithium, cobalt, nickel, REEs, and other minerals, India’s green and high-tech ambitions could be derailed. On the other hand, reckless pursuit of these materials risks environmental damage and social strife. The path forward must navigate both.

First, India should embrace a diversified approach: deepen partnerships with resource-rich democracies while not excluding any supplier that meets environmental and security criteria. For example, joint ventures with Australia for lithium (where India and Japan are collaborating on an EV battery supply chain) or with Argentina and Chile for lithium and copper can provide alternatives to Chinese sources.

Second, India must build domestic capabilities incrementally: the new rare-earth magnet plant in Vizag and planned lithium-ion battery facilities are steps in the right direction. Incentives can spur private companies to invest upstream in exploration and downstream in refining, as long as regulatory frameworks (land acquisition, pollution control) are transparent.

Third, India should invest in recycling and R&D to reduce raw-material dependence over time. Investment in local value addition is a must. The government’s move to subsidise recycling facilities and include critical minerals in circular-economy policies signals early progress here.

Finally, India can leverage its own domestic market to encourage sustainable mining standards globally. By insisting on environmental compliance and fair labour practices in all mineral deals (whether in Canada, Africa, or Australia), India could help build a “responsible supply chain” brand. If India plays its cards right, it can emerge as both a major consumer and a responsible supplier in the global minerals market. The leadership has finally woken up to this challenge. Whether India can integrate its diplomatic stronghold with homegrown innovation without compromising its environmental and social ethos will be the real test.

References

- Reuters. (2025, July 23). India working on rare earths pacts with Brazil, Dominican Republic. The Economic Times. https://m.economictimes.com/news/economy/foreign-trade/india-working-on-rare-earths-pacts-with-brazil-dominican-republic/amp_articleshow/122853812.cms

- Sancheti, T. A. (2025, July 18). India’s Northeast: The new frontier in critical mineral security. Firstpost. https://www.firstpost.com/opinion/indias-northeast-the-new-frontier-in-critical-mineral-security-13908494.html

- Mukherjee, G. (2025, July 23). Critical minerals: India should bide its time and build strategic capacity. Firstpost. https://www.firstpost.com/opinion/critical-minerals-india-should-bide-its-time-and-build-strategic-capacity-13911045.html

- Jain, K. (2025, July 6). Mineral diplomacy in the Indo-Pacific: QUAD cooperation for supply chain resilience. NIICE Nepal. https://niice.org.np/archives/11422

- Baskaran, G., & Schwartz, M. (2025, April 14). The consequences of China’s new rare earths export restrictions. Center for Strategic and International Studies. https://www.csis.org/analysis/consequences-chinas-new-rare-earths-export-restrictions

- Press Information Bureau. (2025, January 29). Cabinet approves ‘National Critical Mineral Mission’ to build a resilient value chain for critical mineral resources vital to green technologies, with an outlay of Rs. 34,300 crore over seven years. Government of India. https://www.pib.gov.in/PressReleasePage.aspx?PRID=2097308

About the contributor: Kumar Ankit is a Research Intern at IMPRI, New Delhi, and has previously interned with the National Maritime Foundation and IISPPR. He is pursuing a Master’s in Political Science from Jamia Millia Islamia and has qualified UGC-NET in Politics, including International Relations. He also holds postgraduate diplomas in International Law & Diplomacy (ISIL) and Iranology (JMI).

Acknowledgement: The author extends his sincere gratitude to the IMPRI team and Ms. Aasthaba Jadeja for her invaluable guidance throughout the process.

Disclaimer: All views expressed in the article belong solely to the author and not necessarily to the organisation.

Read More at IMPRI

AICTE Training and Learning (ATAL) Academy (2023)

The Complex Realities of Water Management